How to Increase ROI on your Ink Spend

7 suggested approaches for printers and converters

Several issues can affect print quality and ink costs on any given job. As an ink provider, we at INX have a front-row seat to the challenges many printers and converters encounter. We identified a list of practical ways you can save money, reduce down-time, and increase the performance and ROI on your ink spend.

1. Conduct a Process Review

Lowering costs in the press room often starts before printing begins. The best first step is to complete a process review to help you uncover any inefficiencies embedded into your current processes. Conducting a comprehensive review will also identify areas for improvement, pinpoint changing equipment needs, and expose any personnel training gaps and requirements.

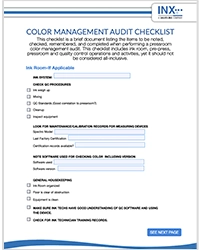

Included in the process review should be a color management audit. Conducting a color management audit should be an essential and ongoing step in ensuring quality and maintaining customer satisfaction. Companies undertaking their first steps into color management auditing may have a common question: what do I need in place to get started? Using a color management audit checklist can aid in the preparation for and implementation of a thorough process review.

Determining how well your ink is performing often requires conducting a total cost analysis to help you understand how efficiently the ink performs on each substrate on which you are printing. It is not enough to just compare price per pound, but a balancing act between price and performance. It’s about ink mileage and the cost per mile, per substrate.

All processes should be documented and customer expectations should be communicated for each job. Process documentation is essential to a well-run press room and should ideally capture everything required to ensure consistent product and service delivery.

Once you’ve completed your process review, INX recommends:

- Creating a template to define and describe your processes

- Ensuring your documentation is clear and concise

- Making the documentation readily accessible to all applicable personnel

- Allowing the documentation to be easily editable with an effective version control system for any document updates

2. Standardize Maintenance & Operations Practices

Many organizations fail to leverage the repeatable nature of maintenance work by creating standardized plans. The benefits of standardizing your maintenance practices often include improved performance, reduced costs, improved work quality, improved safety, and better reliability analytics.

Maintenance encompasses a wide range of complex activities, from daily routine maintenance through equipment inspection and repair to corrective maintenance.

Creating a comprehensive set of maintenance standards that personifies the experience and technology unique to your company is crucial to ensuring that your equipment is running at its peak efficiency and minimizes the risk of unplanned downtime.

Standardizing your operations’ practices also provides positive bottom-line impact. At INX, we recommend:

- Staging all tooling for jobs

- Cutting dies press-side prior to set-up

- Grouping similar jobs to reduce the need for change-overs

- Standardizing on an ink that handles multiple requirements

- Systematizing the process of entering work requests and job plans

Those organizations that take the time to create, communicate, and train their personnel on standard operating procedures often realize improved productivity and increased work quality.

CONTACT

Improve printing productivity in the pressroom while reducing applied costs

Contact a Technical Services Rep

3. Monitor Your Ink Mileage

As you might expect, there are a few ink-specific recommendations that will help you increase your ROI and ensure a well-run press room.

- Ink viscosities should be monitored on an ongoing basis and kept at the lowest possible viscosity that does not negatively affect printability characteristics. This allows for the least amount of solids to be put down and reduces the amount of virgin ink that needs to be used.

- Use ink mileage calculators or dispenser software to make only enough ink needed for the job. This helps to eliminate any excess return and leftover ink.

- Make sure that there is a strong connection between your ink room quality control procedures and your press inking systems (aniloxes, cylinder engravings, etc.). This helps to reduce unnecessary press side adds and increase the amount of ink coming back from the press and set-up time.

4. Take Advantage of Vendor Training

Many organizations fail to take advantage of the training and educational opportunities available from their vendor partners. Many suppliers, including INX International, have educational offerings—e-learning or on-site, that provide access to technical material, diagnostic information, and professional development topics that will help ensure you are getting the most out of your ink. These trainings and professional development offerings provide you with a competitive skillset within your organization that will differentiate you from your competitors and ensure you are aware of and educated in the latest ink and coating technologies.

5. Fingerprint Your Presses

The way each press lays down ink is unique. Each press prints at different speeds, pressures, dot percentages, etc. You need to know exactly how your presses print so that you can deliver the results your customers expect. This is where press fingerprinting is useful. Conducting a press fingerprint can help increase pressroom efficiencies and throughput, reduce waste, improve press speeds, and predictably and repeatedly assure quality packaging that matches customer proofs. A press fingerprint document shows your press prints with the variables (inks, tapes, anilox rolls, cylinders, etc.) identified during the press optimizations. Fingerprinting is also recommended to help you determine whether your press is operating in peak condition (or not) at any given time.

DOWNLOAD

Make sure you are considering all press optimization variables

Download Print Variables List

When fingerprinting, we recommend implementing the G7 Method. G7 is an international standard for calibrating printing presses and the proofing systems to a common, visual, neutral grayscale appearance. It’s a critical component of brand color management and can virtually bring color consistency across multiple platforms around the world. G7 is managed by and is a registered trademark of IDEAlliance, a not-for-profit association. With certified IDEAlliance G7experts on staff, INX has the knowledge and technical resources to help our print partners achieve G7 Master Printer Certification.

6. Outsource the Management of Your Ink Room

Managing an ink room is very complex. A lot of money can get lost from less-than-optimal management of your ink room. Ink comes back from the press and it has to be managed; you can’t just throw it away. You want to try to reuse it, reformulate it, and use it for future jobs. There is no doubt that the companies that do the best job at managing their ink room help the plant perform better and realize increased efficiencies and reduced costs.

For many of our customers, ink mixing and color matching isn’t their core business. They look to us to bring that service—managing the ink room—to them. Having a company such as INX manage your ink room helps to enhance and augment the skillset of your organization and make your ink room more productive and efficient; and it can lower your applied costs by:

- Manufacturing batches of ink

- Overseeing the ink room and customer projects

- Managing the customer / job schedule

- Ensuring ink quality control

- Performing press-side trouble-shooting

- Scheduling orders, creating forecasts and estimates, and maintaining inventory

For more information on the benefits of inplant ink operations read our blog post: Exploring The Benefits of Inplant Ink Operations

DOWNLOAD

Ink room management solutions that increase your efficiencies and reduce cost

Download Brochure

7. Use Quality Inks

Some printers focus too much on price per pound and fail to consider mileage, make-ready time, ease of use, and ink stability. Poor quality inks that lack these properties result in expensive press downtime and decreased productivity.

Quality inks—those that quickly reach ink/water balance and come to color faster—will result in less substrate waste and will ultimately lead to better performance, higher production speeds and greater print capacity.

There are several ways to ensure ink quality doesn’t decrease productivity

- Understanding Expected Color Tolerances.

Printing productivity and profitability often hinge on managing color tolerances, and being unaware of them is like driving without a destination in mind. Tolerances may begin internally or may be determined by customer expectations. - Ensuring Ink Performance Through Quality Control (QC)

A strict quality-control program can improve improve color consistency and repeatability. In selecting an ink manufacturer to help make your production hours profitable, it is important to ask how they manage QC in the raw materials used and in their production process. - Prioritizing Ink Selection

The importance of ink selection has grown as specialized formulations have proliferated and available stocks include a broad range of porous and non-porous materials. You want to ensure the ink used is correct for the substrate and the purpose of the printing, enabling printers to minimize waste and maximize production time.

To learn how Color tolerance, quality control, and ink selection increase pressroom productivity read our blog post Three Ways to Ensure Ink Doesn't Decrease Productivity

Conclusion

For printers and packaging converters, ink is one of the main consumables that can be managed to reduce costs and realize an increased return on your ink spend. As the third largest producer of inks in North America, with full-service subsidiaries in Europe and South America, we have helped our customers implement all or some of the recommendations I shared in this post in order to save money, reduce downtime, and increase the performance and ROI of their ink spend.

INX stands ready with the experience and expertise needed to make pressrooms more productive, improve efficiencies, and lower applied costs.